News from the ROI world

23 Febbraio 2026

Logsys powers logistics with Interroll technology

Thousands of items, thousands of packages, hundreds of pallets – moving smoothly, every day.

09 Febbraio 2026

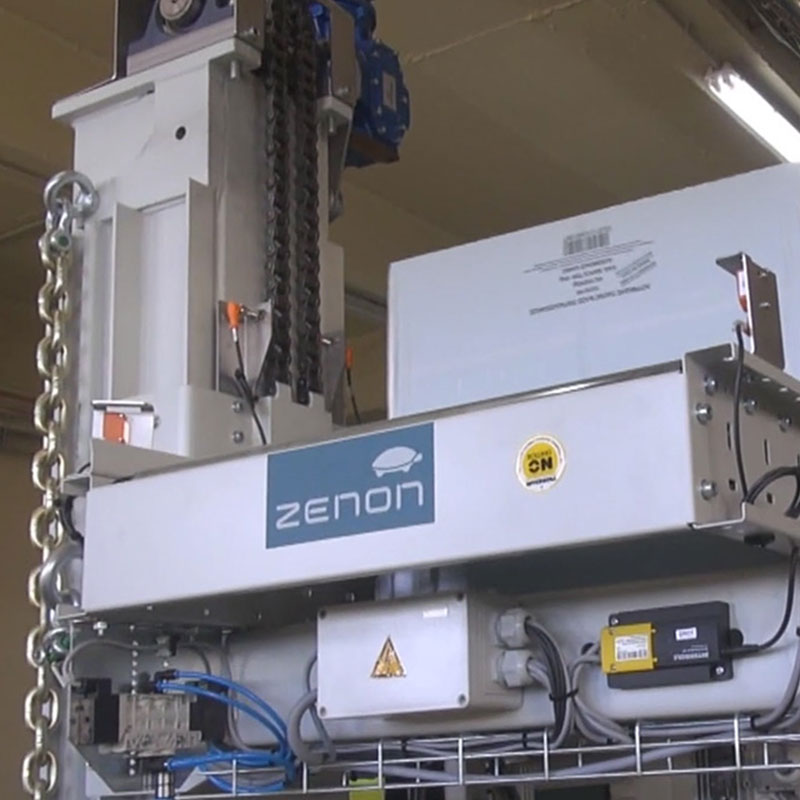

AP Dataweigh puts real-time accuracy in motion

Packages don’t pause – and neither does precision.

The U.S. ROI partner impresses with its latest Caseweigher system that weighs products in motion, captures data in real time, and connects it instantly to the warehouse management system.

30 Gennaio 2026

The future sticks: smart labeling by AuthenTEK

The new TEKaLabel system brings advanced flexibility and control to automated print-and-apply labeling.